|

|

|

Introduction

|

|

|

******** The

electronic data in this Section has largely been supplied by CDI

electronics, a division of Rapair, Inc. CDI electronics has been

the leader in outboard marine Ignition technology since 1983, and

their products are marketed under the name of "Quick Strike

ignitions". Outboardparts.com features CDI Electronic Products

throughout our site. This information is supplied as a service

guide only and Outboardparts.com is not liable for any

misunderstandings, errors or omissions regarding this

information. The information has been obtained from actual Unit

analysis, parts manuals, and other sources.

********

|

|

| The purpose of this brochure is to give the marine technician

a general overview or the types of test equipment and their use.

The most common, easy to use, test equipment will be

covered. |

| Due to the rapid development of computerized EFI (Electronic

Fuel Injection) and ECU Ignition systems, more complicated and

expensive test equipment will be developed for the marine

industry, just as it has been developed for the automotive

industry. Some newer equipment will include the use of scope

meters (such as the Fluke 98), ECU and EFI testers, digital

analyzers, and computer interface testers. Hopefully, the newer

test equipment will be user friendly and many Troubleshooting

problems will be diagnosed with less complicated equipment. |

|

| The test procedures at the end of this brochure are intended

to give the technician a better understanding of the most common

failures and allow testing with minimal equipment. |

|

|

Test Equipment and Measurements

|

|

|

| I. VOM (Volt-Ohm-Meter) Multimeter |

|

A. Analog meter - The analog VOM is a dial/needle

movement with multiple switch settings and ranges on each

setting. This meter usually requires "calibrating" of the scale

before use.

|

|

They normally consume batteries at a fast

rate.

|

|

| B. Digital meter - The digital VOM uses a digital display to

indicate the readings. Of the following types, the manual and

autoranging are the most popular |

|

| 1. Manual range setting - The measurement range is

selected by a switch, i.e. 20 ohm, 200 ohm, 2k ohm, 200k ohm and

20M ohm. The symbol for ohms is W. |

| |

| 2. Autoranging - A true autoranging meter will

automatically select the correct range for the measurement being

taken, i.e., you can measure 20 ohms and 2k ohms without changing

anything on the meter. The Type of measurement still has to be

manually selected, i.e., AC Volts, DC Volts, Ohms, AC Amps and DC

Amps. |

|

|

| 3. Manual / Autoranging - Some meters have both manual

and automatic settings, i.e., the Fluke 88, Fluke 29, etc. |

|

|

| 4. Ranges - As a reminder, when referring to

electronics, the k is 1000, i.e., 1k ohm is 1000 ohms and 20k

ohms is 20,000 ohms. The M is 1,000,000 i.e., 2M ohm is

2,000,000 ohms. |

|

|

| II. Peak Reading Voltage Measurement |

|

| A. DVA (Peak Reading)

Voltmeters - Specialty meters for measuring average DC voltages

and AC voltage spikes on Ignition systems. Some of the more

common meters include the Stevens CD-77, Merc-o-tronic and ESI

meters with DVA ranges. |

|

|

| B. Multi-use Voltmeters with

DVA Adapters - Analog or digital VOM (volt, ohm meters) using a

plug-in DVA adapter to measure DVA voltages. Accuracy varies

quite a bit between manufacturers and types of meters when taking

DVA readings. The CDI/Rapair 511-9773 peak adapter is highly

recommended for use with all Fluke meters. |

|

|

|

| III. RPM (Tachometer) Measurements |

|

| A. Inductive Tach Measurements |

| This type measurement is made by clamping an

inductive pickup probe on one of the spark plug wires. Very few

of the inductive systems will work well on two cycle CD ignitions

due to the RF and microwave noise being generated. The Fluke 88

Multimeter used with the CDI/Rapair 511-9788B two cycle adapter,

is highly recommended. The Merc-o-Tronic Inductive Tach and the

CDI/Rapair Tach Adapter (P/N 511-9785) are some of the units

recommended for both two and four cycle service. Inductive

tachometers can be a real time-saver when trying to find a high

speed miss by comparing the readings on all cylinders, i.e., if

one or two cylinders shows a big difference in comparison to the

other cylinders. The use of inductive tachometers is recommended

for detection of double firing cylinders. If one cylinder shows

twice the RPM of the other cylinders, it is probably double

firing. |

|

|

|

| B. Reflective Tach Measurements - These

are optical tachometers, that use a piece of reflective tape on

the flywheel or pulley. |

|

| C. Contact Tachometer - NOT

RECOMMENDED for Outboard Use. |

| Uses a center hub rotator and counts the

RPM.. |

|

|

| D. Pulse Tachometer - This

Tach is activated by the AC signal from the Stator. The RPM

signal is related to the number of Pulses received from the

Stator. |

|

|

| IV. Temperature Measurements |

|

| A. Thermocouple / Meter System |

| This is probably one of the most useful systems.

The Fluke 51 and 52 temperature meters, or the accessory

temperature attachments for the Fluke meters, are capable of

measuring exhaust gas temperature, water temperature, head and

block temperature. Various probes are available for different

types of measurement with the bead probe being one of the most

useful. The bead probe can be positioned on the block with the

use of duct tape. |

|

|

| B. Infrared Temperature

Probes |

| They can be used to measure temperature at

various points on the engine or water temperature without

contact. However, some running engines generate too much

electronic static and will interfere with the infrared sensor

readings. Holding the temperature probe too close may cause the

Ignition noise to ruin the Unit. |

|

|

| C. Temperature Sticks, Paint

or Labels |

| These can be used for quick measurementof over

heating conditions. |

|

|

|

| V. Pulse Measurements / Frequency Measurements |

| This is a good method to check electronic fuel

injection systems (EFI). A measurement of the injector Pulses at

a set RPM can determine if the injection system is performing

properly. At the current time there are few recorded

measurements on the various EFI systems. The Fluke 88 meter is

one of the meters designed to measure EFI Pulse rates. |

|

|

| VI. Resistance Measurements |

| This is one of the first and easiest

measurements that needs to be taken on an Ignition system. The

charts in the back of this brochure are furnished as a guide. Be

aware that temperature can make a slight difference in the

readings. The higher the temperature - the higher the resistance

reading is going to be. One final note, a Stator or Trigger can

test fine with an ohmmeter and still be bad. |

|

|

| VII. Current Measurements |

|

| A. Direct Volt Amps (DVA) |

| One of the most important

measurements to be taken on Ignition systems are voltage

measurements using a DVA meter, or peak reading (DVA) adapter

with a good VOM. The Fluke *a Kit is highly recommended by out

Technical Service Department. The charts in the back of this

brochure give the readings for a majority of the engines. On an

engine with a split Ignition, if only one side fires, compare the

readings between the sides. Typically, the DVA readings for

Yamaha and Suzuki will be close to that of Mercury Outboard. A

simple test on rectifier/regulators (except OMC

rectifier/regulators without cooling fins on the bottom) can

sometimes be a time-saver. with the engine running at

approximately 1200-1500 RPM. DVA test from each yellow Wire to

engine ground. The readings should be within 11/2 volts of each

other, i.e., if one Wire reads 20 volts - the other has to read

between 18 1/2 and 21 1/2 volts. If one Wire reads low, mark the

Stator and rectifier Wire with the low reading, shut the engine

down and swap Stator wires. Crank the engine up and repeat the

test. Whichever part with the striped Wire that has the low

reading is bad. Repeat the test for yellow wires to the red Wire

going to the battery / solenoid. |

|

|

| B. DC Voltage |

| Most battery CD Ignition modules are sensitive

to low battery voltage and battery reversal. During cranking, a

DC voltage level at the pack of less than 9 !/2 Volts is

unacceptable and indicates a problem in the Harness, keyswitch,

starter or battery. WOT voltages above 16 volts will blow most

battery ignitions. Problem is likely to be either the battery or

cables. |

|

|

|

| VIII. Current Measurements |

|

| This is a good way to check the

regulator/rectifier battery charging operation in the charging

system. The 10 amp charging system can be checked with a good VOM

that has up to 10 amp capability (Fluke 29,73,88, etc.). The red

Wire is disconnected from the rectifier, the one meter probe is

placed on the connection, and the other is placed on the red

Wire. |

|

|

| Warning! Make sure you do not exceed 10 amps or

touch ground with one probe. This could damage the meter.

The 35 amp charging system requires an inductive pick up or a

high current amp adapter, such as CD/Rapair's 511-9772 (1-400

amp). Remember, on outboard charging systems at idle speed the

current is @ 1/5 of the current rated. |

|

|

| IX. Battery CD Tester |

| |

| This is used to test battery CD modules on the

engine by replacing the points or triggering device

electronically. The CDI 511-9701 Battery CD Tester is highly

recommended due to its ability to fire the Ignition systems up to

3000 RPM without the engine running. It can be used to test the

CD module, distributor cap, Ignition coil and plug wires.

Additionally, the tester can be used to test Mercury Outboard EFI

injectors. |

|

|

| X. EFI Tester |

| |

| Electronic fuel injection testers are available

for use with the specific type of EFI system it was designed for.

Use of these testers are not covered in this brochure. |

|

| |

| XI. Trigger Tester |

| |

| A break through by CDI/RAPAIR (511-9710) allows

you to test most Mercury Outboard, Mariner, Force Outboard Motor,

Chrysler triggers and OMC's Quick Start timer bases on the

engine. The Unit can be used to test points, preamp triggers,

Mercury Outboard battery CD triggers, hall effect triggers,

Alternator driven Ignition triggers, and can be used to check

injection Pulse from Mercury Outboard EFI modules. |

|

|

|

Tricks to Testing with Minimal Test

Equipment

|

|

|

|

all Engines

|

|

|

| Intermittent Firing: This problem can be very hard to

isolate. A good inductive tachometer (fluke 88 is recommended)

can be used to compare RPM on all cylinders up through wide open

throttle. A big difference on one or two cylinders indicates a

problem. |

|

|

| Two or more cylinders misfiring: It is recommended that both

power packs be replaced, unless the problem is a bad

Trigger. |

|

|

| Engine continuously blows power packs: When an engine starts

blowing power packs repeatedly, especially on the same cylinders,

replace the Ignition coils on those cylinders. The inductive

kickback from a bad coil can destroy the packs, even if the coils

check good with all known tests. A Stator that test good can also

be sending spike voltages to the packs causing them to fail

repeatedly. |

|

|

| Visually check the Stator, Trigger and flywheel: Cracks,

burned marks and bubbling on the Stator or Trigger indicate a

severe problem. If the Stator shows bubbling around the battery

charge windings, more than likely you will have to replace the

rectifier/regulator in addition to the Stator. Signs of rubbing

on the flywheel usually indicate a bad upper or lower Bearing.

Check both the outer Trigger magnets for signs of cracking and to

be sure that they are not loose. |

|

|

OMC

|

|

| Open type timer bases: When all cylinders fire with the spark

plugs out, but one or more cylinders quit when the spark plugs

are reinstalled, regapping the timer base may solve this

problem. Please refer to the Troubleshooting guide for OMC power

packs and CD's item #8. |

|

| Quick Start timer bases: These timer bases cannot be checked

like the other timer bases. Please refer to the Troubleshooting

guide for OMC power packs and CD,s item #5. |

|

| Engines with SLOW features: If the complaint is that the

engine will not slow down after a few minutes and starts shaking

real bad, (but the engine is NOT overheated) try replacing the

temperature switch (the one with the white/black and tan wires

coming out). Check routing of tan wires. Relocate as far from the

spark plug wires as possible. Check blocking diode in engine

Harness. |

|

|

Mercury Outboard 6 Cylinder with ADI

Ignition

|

|

| No fire on the 1,3,5 or 2,4,6: Swap red and red/white wires,

also blue with blue/white wires. If the problem moves to the

other set of cylinders, the Stator is at fault. Disconnect

rectifier and retest. If the engine fires normally, replace the

rectifier. If no change, we recommend replacement of the Stator.

If you replace the Stator and the problem remains try another

flywheel, if possible. |

|

| No fire on one cylinder: Since this condition can be caused

by the opposite switch box (pack), disconnect the white/black

jumper between the packs and retest. If the dead cylinder starts

firing, replace the pack that was firing all three cylinders. As

a verification, swap the Trigger and spark plug Wire to the

cylinder closest to the dead cylinder, (i.e., if #1 is dead, swap

the brown Trigger Wire with the white one). If the problem moves

to #3, replace the opposite power pack (switch box). If #1 is

still dead, swap the green and green/white coil wires. If the

problem moves to #3, replace the power pack (switch box). Please

remember to put the Trigger wires in the correct order after you

finish. |

|

| Always check the bias circuit: Disconnect the jumper between

the packs on the white/black posts. Check the resistance from the

white/black posts on each pack to engine ground. Standard packs

will read from 13-15,000 ohms. Racing boxes will read

approximately 9,600 ohms. MAKE SURE THAT the BIAS Reading is the

Same on BOTH Packs!!! If the bias is out of specification on one

pack you must replace both packs to prevent future damage. This

circuit effects Ignition timing and could cause a powerhead

failure. |

| for more detailed information, please refer to the

Troubleshooting guides on the other pages. |

|

|

Troubleshooting OMC Battery CD

ignitions

|

|

|

| Recommended Tools: |

| for DVA: |

Fluke Multimeter with CDI #511-9773 Peak Adapter, (or CD-77)

and CDI #511-9770 |

|

CDI #511-9701 Battery CD Tester |

|

CDI #511-9766 Spark Gap Tester |

|

Jumper Wires |

|

A Reliable Volt/Ohm Meter (if the CD-&& is used for

the DVA |

| CAUTIon; DO NOT Use A MAINTENANCE FREE Battery

with these TypeS of ignitions As theY TEND To OVERCHARGE and BLOW

the Packs.> Typically 17 Volts +. |

|

| Note: A large portion of the problems with the

battery CD units are caused by low battery voltage or bad ground

connections or high battery voltage. Low Voltage symptoms are

weak erratic firing of cylinders. Misfiring after a few minutes

of running can be caused by excessive (Over 15.5 Volts DC)

voltage at the pack - See #2 below. |

|

| 1) Check all battery and ground

connections. |

|

| 2) Check the Voltage on the red (or purple)

Wire at the CD Unit. |

| If the voltage is less than 9 1/2

volts during the cranking there is a problem in the battery

circuit. These units require at least 9 1/2 volts to fire

properly. Connect a jumper Wire directly from the battery (+)

terminal to the red (or purple) Wire. Retest. ATTENTIon: In order

to kill the engine if it cranks, the jumper Wire must be

disconnected and/or choke the engine. If the engine still fails

to crank, recheck voltage as above. If low, replace the battery

and retry. Warning: Check he voltage on the red (or purple) Wire

at the CD Unit through the RPM range. At no time should the

voltage exceed 15.5 Volts DC. |

|

| |

| 3) Disconnect points and/or sensor Wire and

connect a battery tester. |

| Hook up the Battery CD Tester according to the

operators manual and align rotor with spark plug Wire. Connect a

spark gap to all spark plug wires and turn the Ignition switch

on. If the CD Unit fires only to one spark plug Wire, check the

points, sensor, anti-reverse spring and wires for breaks and

shorts. If ANY other spark plug Wire fires besides the one the

rotor is aligned with, the distributor cap and rotor should be

replaced. The Battery CD tester will fire the system to

approximately 3000 RPM. If the Battery CD tester (511-9701) is

not used, strike points Wire against engine ground. for the

sensor, strike the two wires together. The CD Unit should fire

every time. If the CD Unit fails to fire, it is usually bad. |

|

| |

| 4) Points type Ignition. |

| Disconnect points Wire and check voltage on the

points Wire. You should read close to battery voltage with the

key switch on. No voltage means a bad pack. If OK, reconnect the

points Wire. Using the piercing probes (511-9770) connect the DC

volt meter to the points Wire. Turn the switch on and slowly

rotate the flywheel. You should see the voltage fluctuate up and

down. |

|

| |

| 5) Check the Ignition coil. |

| An open, cracked or poorly grounded coil can

burn out a battery CD Unit. |

|

| |

| 6) Check the DVA voltage on the primary input

Wire to the coil. |

| Reading should be approximately 200 volts or

more. |

|

| |

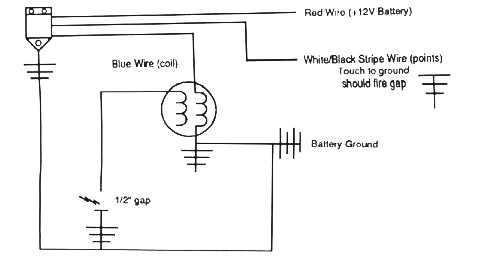

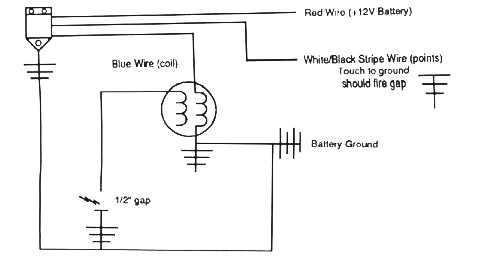

| 7) Simplified bench test: |

|

|

|

Troubleshooting OMC Power Packs and

CD's

|

|

| Recommended Tools: |

| for DVA: |

Fluke Multimeter with CDI #511-9773 Peak Adapter, (or CDI

#511-9770 Piercing Probes |

|

CDI #5119-710 Trigger tester (for use with '88-'96 V8, V8

Quick Start timer Bases |

|

CDI #511-9766 Spark Gap Tester |

|

CDI #553-2697, 553-2698, 553-2699 Pin Removal and Insertion

Tools |

|

CDI #553-9702 Gap Gauge |

|

Jumper Wire |

| Note: If CD-77 is used for DVA, you will need a

good volt/ohm meter. |

|

| NOTICE: Initial DVA readings should be taken with

everything hooked up. |

|

| 1) Check the flywheel for cracked and lose

magnets. |

|

| 2) Disconnect the kill Wire(s) from the pack and

retest. |

| Connect a DC voltmeter between the kill wires

and engine ground. Turn the Ignition switch on and off several

times. If at any time, you se DC voltage appearing on the meter,

there is a problem in the battery Harness or the Ignition switch.

NOTE: At no time should you see battery voltage on any kill

wires. |

|

|

| 3) Visually inspect Stator for cracks or

leaks: |

| If found, replace the Stator, Burnt marks of

discolored areas on the battery charge windings indicates a

possible problem with the rectifier. |

|

|

| 4) Unit will not fire: |

| Disconnect the kill Wire AT the Pack. Check for

bare or broken wires on the Unit, Stator and timer base. Measure

DVA voltage of the Stator with everything connected. Readings

should be approximately 150 volts or more. On Standard CD types,

check DVA voltage on the timer base white Wire. Voltage should be

approximately 150 volts or more (Quick Start units usually have

the white Wire tied to ground inside the pack). If the reading is

good on the Stator but low on the white Wire, the timer base is

usually bad. Disconnect the rectifier. If the engine fires,

replace the rectifier. |

|

|

| 5) '88-'98 V6-V8 and 93-98 3 cylinder Quick

Start timer bases: |

| Disconnect the timer base. Using the Fluke

meter, set to ohms scale, and one of the piercing probes, connect

the red lead from the meter to the white Wire in the Amphenol

connector from the timer base. Use the black lead from the meter

and check to all of the pastel colored wires in both connectors

from the timer base. all of the readings should be fairly even,

normally between 1 and 2 meg ohms measured with a Fluke meter.

with the red lead still connected to the white Wire, connect the

black meter lead to the black/white Wire in the opposite

connector from the timer base. You should read approximately 220

ohms. If one or more cylinders are out of line, (I.E. all the

rest are reading 1.2 -1.8 meg ohms and one reads 0.898 or 2.2 meg

ohms) the timer base is usually bad. |

|

| |

| 6) '92-'96 Looper units with optical

triggers: |

| DVA check the Stator. Each set of brown wires

should read at least 150V (950-1050 ohms) and 12 volts between

the two orange wires from the power coil (50 ohms on the gray

sleeved Stator and 97 ohms on the black sleeved Stator). Note:

These units require special spark plugs and the GRAY spark plug

wires. If the pack only fires when you remove the plug connector

containing the kill wires, use a jumper Wire to connect the kill

wires in the pack. If the pack still fires, there is a problem in

the Harness, safety circuit or Ignition switch. A no fire

situation with the jumper in place indicates a bad pack. |

|

| |

| 7) '89-'95 4 Cylinder Looper units: |

| If the engine misses on one cylinder with the

white/black temperature Wire hooked up and does not with it

unhooked, this is usually the timer base causing the

problem. |

|

|

| 8) for PP2, 3, and 4 units: |

| If one or more cylinders will not fire with the

spark plug installed], check the timer base resistance between

sensor leads: PP2, from white/black to black/white; PP3 from

black/white to all all whit/blacks; PP4 1-3 and 2-4, readings

should be 10-20 ohms for all sensor coils. (some of the older

units with the metal cased CD's read 8-14 ohms). Regapping may

solve the problem. CDI Gap Gauge 553-9702 is recommended for PP3

and PP4. To regap, remove the epoxy covering and loosen the small

nuts on the center bolts going thru the heat shield. Loosen the

anchor screws holding down the sensors. Slide the sensor in

toward the Crankshaft until it touches the gap gauge. (553-9702)

or the metal stop at the bottom of the sensor. Paint the face of

the sensor or the Trigger magnet on the flywheel, with a contact

detector, and reinstall the flywheel. Crank the engine over

several times and remove the flywheel, checking to see if the

Trigger magnet is striking the sensor face. |

|

|

| 9) Engine will not kill: |

| Remove the black/yellow kill Wire from the

rubber connector to see if the pin is broken. Check the kill

circuit in the pack by using a jumper Wire connected to the

black/yellow Wire coming out of the pack and shorting it to

ground. If this kills the engine, the kill circuit in the Harness

or the boat is bad, or the Ignition switch is bad. |

|

|

| 10) Coils fire with spark plugs out but not

in: |

| Check for dragging starter or low battery

causing slow cranking speed. DVA test the timer base. |

|

|

| 11) Engine runs rough on one bank (4, 6 and 8

cylinder engines with CD ignitions): |

| DVA check Stator voltage to both sides. The

readings should be fairly equal. If it exceeds 400 volts, replace

the pack on the bank. If unequal, swap banks with the Stator

leads and see if the problem moves with the Stator leads. If it

does, replace the Stator. Disconnect one of the black/yellow kill

wires, AT the Pack. If the problem goes away, replace the pack

that was running smooth as is probably has a bAdBlocking

diode. |

|

| |

| 12) Intermittent firing on one or more

cylinders: |

| Can be caused by low voltage from the Stator of

a bad timer base. DVA test Stator and timer base. Disconnect the

rectifier and retest. If the problem disappears, replace the

rectifier. If it doesn't replace the pack |

|

|

| 13) Check for broken wires and terminals; |

| Especially check inside the rubber Amphenol

plug-in connectors. We recommend that you remove the pins from

the connectors and visually inspect them. |

|

|

|

Troubleshooting Mercury Outboard Battery

CD ignitions

|

|

| Recommended Tools: |

| for DVA: |

Fluke Multimeter with CDI #511-9773 Peak Adapter, (or

CD-77) |

|

CDI #511-9701 Battery CD Tester |

|

CDI #511-9710 Trigger Tester |

|

CDI #511-9766 Spark Gap Tester |

|

Jumper Wires |

|

A Reliable Volt/Ohm Meter (it the CD-77 is used for the

DVA) |

| CAUTIon; DO NOT Use A MAINTENANCE FREE Battery

with these TypeS of ignitions As theY TEND To OVERCHARGE and BLOW

the Packs. Typically 17 Volts +. |

|

| Note: A large portion of the problems with the

battery CD units are caused by low battery voltage or bad ground

connections or high battery voltage. Low Voltage symptoms are

weak erratic firing of cylinders. Misfiring after a few minutes

of running can be caused by excessive (Over 15.5 Volts DC)

voltage at the pack. - Warning : Check the voltage on the red (or

purple) Wire at the CD Unit through the RPM range. At no time

should the voltage exceed 15.5 Volts DC. |

| |

|

Warning!! Battery REVERSAL WILL USUALLY DESTROY

Battery CDs and TRIGGERS.

|

|

| 1) Check all battery and ground

connections. |

|

| 2) Dead or no fire until you release the key

switch: |

| Disconnect the Mercury Outboard

switch and reset, if the engine fires, replace the Mercury

Outboard switch. Check the voltage on the red and white Ignition

wires at the CD Unit. If the voltage is less than 9 1/2 volts

during cranking there is a problem in the battery s or the

Ignition switch box. These units require at least 9 1/2 volts to

fire properly. On a 332-2986 switch box, check the voltage on the

brown terminal (white/black for 332-47960 where the Trigger is

hooked up. It requires at least 9V at cranking. DVA check

between the white and black wires (black and blue on 332-4796).

You should read at least 2 1/2 volts at cranking. Connect a

jumper Wire directly from the battery POS (+) terminal to the red

and white Ignition wires (the red Wire is not needed for the CDI

units). CAUTIon: DO NOT Connect the JUMper Wire To the WHITE

Trigger Terminal. Retest: ATTENTIon: in order to kill the

engine if it cranks, the jumper Wire has to be disconnected

and/or choke the engine. If the engine still fails to crank,

recheck voltage as above. If low, replace the battery and retry.

If there is still no fire, disconnect points Wire (or Trigger

wires) and connect the Battery CD tester (511-9701), according to

the instructions in the manual, and align the rotor with a spark

plug Wire. Connect a spark gap tester (511-9766) to all spark

plug wires and turn the Ignition switch on. If the CD Unit fires

to only one spark plug Wire, check points Wire (for breaks or

shorts) or Trigger. If ANY other spark plug fires besides the one

the rotor is aligned with, the distributor cap and rotor should

be replaced. The Battery CD tester will fire the system to

approximately 3000 RPM. If the Battery CD tester is not used, see

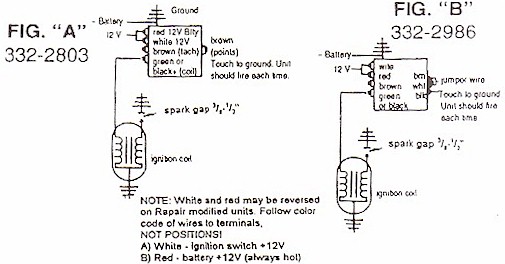

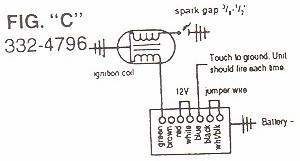

related drawings on the Schematic page (following). If the CD

Unit fails to fire with this hookup, it is usually bad. Following

the instructions included with the Trigger Tester (511-9710)

check the Trigger to see if it is good or bad. |

|

|

|

| 3) Engine cranks and fires as long as starter

is engaged: |

| This problem usually indicates a bad

Trigger. |

|

|

|

| 4) Check the Ignition coil. |

| An open, cracked or poorly grounded coil can

burn out a battery CD. |

|

|

|

| 5) Check the DVA voltage on the primary input

Wire to the coil. |

| Using the fluke meter with the peak reading

voltage adapter (5111-9773), or CD 77. The reading should be

approximately 100 volts or more for OEM CD's, and 200+ for CDI

electronics units. |

|

|

|

| 6) Inline engines with internal exhaust

plate: |

| If the engine speeds up when you remove one

spark plug Wire, the internal exhaust plate is more than likely

warped. The following tests can be performed on the bench or on

the engine. NOTE: Disconnect the Trigger mechanism prior to

testing. |

|

|

|

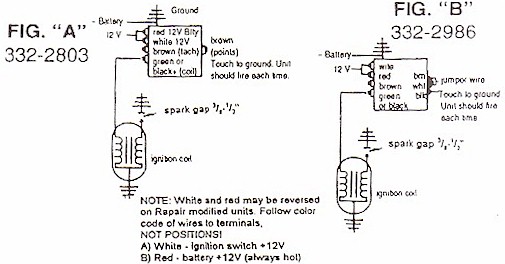

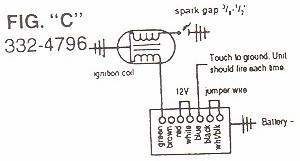

Basic Mercury Outboard

Schematics

|

|

|

|

|

|

|

|

|

Troubleshooting Mercury Outboard

Alternator Driven Ignition

|

|

| Recommended Tools: |

| for DVA : |

Fluke Multimeter with CDI #511-9773 Peak Adapter and: |

|

CDI #5119770 Piercing Probes |

|

CDI #511-9710 Trigger Tester |

|

CDI #511-9766 Spark Gap Tester |

|

Jumper Wire |

|

A Reliable Volt/Ohm Meter (it the CD-77 is used for the

DVA) |

|

| NOTICE: Initial DVA readings should be taken

with everything hooked up. |

|

| 1) Disconnect the kill Wire(s): |

| Connect a DC volt meter between the kill wires

and engine ground. Turn the Ignition switch in and off several

times. If, at any time, you see DC voltage on the kill wires,

there is a problem with the Harness of Ignition switch. Battery

voltage on the kill circuit will destroy most CD units. |

|

|

| 2) Visually inspect Stator for cracks or

varnish leakage: |

| If found, replace the Stator. Burned marks or

discolored areas on the battery charge windings indicate a

possible problem with the rectifier. |

|

|

| 3) Unit will not fire: |

| Disconnect kill Wire AT the Pack. Check for

broken or bare wires on the Unit, Stator and Trigger. Check the

DVA voltage of the Stator, (on 3 and 6 cylinder models read from

each red and blue Wire to engine ground; on 4 cylinder models

read between the two red wires and between the two blue wires),

with everything connected. The readings should be approximately

180 volts or more on the blue wires. and 30 or more volts on the

red wires. Disconnect the rectifier. If the engine fires replace

the rectifier. |

|

|

| 4) Engine will not kill: |

| Check the kill circuit in the pack by using a

jumper Wire connected to the black/yellow terminal or Wire coming

out of the pack and shorting to ground. If this kills the engine,

the kill circuit in the Harness or on the boat is bad, possibly

the Ignition switch. |

|

|

| 5) High Speed Miss: |

| Disconnect the rectifier and retest. If the miss

is gone, the rectifier is usually at fault. If the miss still

exists, check the DVA voltage (between the red wires on 4

cylinder, or red wires to engine ground on 3 &6 cylinder) of

the Stator at high speed. NOTICE: Use caution when doing this and

do not exceed the rated voltage range of your meter. The readings

should show a smooth climb in voltage. If there is a sudden or

fast drop in voltage right before the miss becomes apparent, the

Stator is usually at fault. If there is no indication of the

problem, it could be a small water leak in one or two

cylinders. |

|

|

| 6) Coils fire with spark plugs out but not

in: |

| Check for dragging starter or low battery

causing slow cranking speed. DVA test Stator and Trigger.

Disconnect rectifier, regulator and retest. If the problem goes

away, replace the rectifier and/or regulator. |

|

|

| 7) Engine runs rough on top or bottom two

cylinders (4 cylinder engines): |

| Check DVA voltage of the Stator between blue

wires and to ground. Readings to ground should be fairly equal.

If unequal, swap Stator leads (blue with blue/white, red with

red/white) and see if the problem moves with the Stator leads. If

it does, replace the Stator. Check Trigger resistance between #1

& #2, compare to resistance between #3 & #4. The readings

should be approximately 850 to 1250 ohms for OEM (950 ohms for

CDI). for test purposes only, swap the Trigger leads 1 &3,

and 2 &4. If the problem moves, replace the Trigger. If it

does not move, swap coil primary wires, and replace the pack if

the problem remains on the same cylinder. |

|

|

| 8) No fire on one bank (odd or even cylinders

on inline 6 cylinder engines): |

| Check the DVA voltage of the Stator, checking

from each red Wire to engine ground. The readings should be

approximately 180 volts or more on the blue wires and 30 or more

on the red wires. if a DVA meter is not available, swap both sets

of the Stator wires between the packs. If the problem moves,

replace the Stator. If the problem stays on the same bank, swap

physical location and all connections of the two packs. If the

problem stays with one pack, replace the pack. NOTE: If the pack

is bad, it is recommended that BOTH packs be replaced if the

packs are not manufactured by CDI or Rapair. If the packs

lose ground, internally or externally, the packs manufactured by

other sources usually have severe damage to the bias circuit and

need to be replaced as a set. The packs manufactured by CDI will

withstand loss of ground connection, normally with no damage to

the bias circuitry. In most cases you will just lose fire. |

|

|

| 9) Intermittent firing on one or more

cylinders: |

| Disconnect the white/black Wire between the

packs on a 6 cylinder and retest. If all cylinders now fire,

replace both packs as there is a problem in the bias circuitry.

On all others, check for low voltage from the Stator and Trigger.

Disconnect the rectifier and retest. If the problem disappears,

replace the rectifier. |

|

|

| 10) all cylinders fire but the engine will not

crank and run: |

| On 3 and 6 cylinder engines, disconnect

white/black Wire and check the bias circuit (white/black

terminals) resistance to engine ground. Readings should be

approximately 15,000 Ohms for Standard packs and 9,600 Ohms for

racing units. If the readings are correct on the packs, index the

flywheel and check the timing on all individual cylinders. If the

timing varies, replace the pack. On 4 cylinder engines the bias

circuit is internal, therefore the only way to verify proper

operation of the bias circuit is to index the flywheel and check

the timing on each cylinder. If the timing is off, replace the

packs. |

|

|

|

|

Return To:

CDI Troubleshooting home page

|